I realized that working on tools and jigs can be more challenging and more time consuming that guitar building itself

Welcome to the club

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Outfitting your shop! http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=5408 |

Page 1 of 2 |

| Author: | af_one [ Thu Mar 02, 2006 11:54 am ] |

| Post subject: | |

Hi, I first want to say that in the last month I have sure learned alot here. The time has come and I am just about tooled up to start building. I make custom handgun grips and have learned that asking questions saves money--there are many tools I ahve purchased to build grips with that I ahve never used, so I thought I would spare myself some trouble and ask here. First, I have purchased a bender, gobar deck, radious dishes and binding cutter system from Bluescreek. Great products and even better service. I've purchased some woods from RC Tonewoods and Colonial--outstanding again. I plan to keep supporting the sponsors here. I only need to buy hand tools and thats where my question comes in--If you were tooling up your shop all over again, what would you buy? Planes, chisels, starightedges, fret tools??? What would you recommend?? Money is not the primary objective, I don't mind paying for goo tools that wil be used, so I'm not doing this on the cheap. Please tell me about your favorite tool, the ones you could not do without? The best you've found, etc. Thanks for enduring my long rant, but I think this may prove very educational. |

|

| Author: | LanceK [ Thu Mar 02, 2006 12:15 pm ] |

| Post subject: | |

Sounds like you have a great start! For chisels, ya cant beat the blue handled Marples for 20 bucks! I also have a sears craftsman 6" plane that I use all the time, way more than any of my other larger or smaller planes. A good laminate trimmer is handy, as it a router, you can pick up both on ebay for aound 60 or 80 bucks. For fretting, I use a plastic headded hammer to pound the frets in, a nice set of side cutters are handy, and if you plan to use bound fretboards, get Stewmacs fret nippers, there awesome! Also, while were on Stewmac, they have a nut slot ruler that is extreamly handy, and there stright edges are great, I also love the Ibex fret rule. They also have the new circle cutter that is a must. Hmmm, what else? well I could go on and on, im sure others will have ideas. If you plan to slot your own boards, Stewmacs fretslotting system is great, Shane from High Mtn tonewoods has some nice looking fret slotting blades too. OH! I love the digital calipers stewmac has too. Hope this helps |

|

| Author: | peterm [ Thu Mar 02, 2006 12:19 pm ] |

| Post subject: | |

I realized that working on tools and jigs can be more challenging and more time consuming that guitar building itself

Welcome to the club

|

|

| Author: | Joe Beaver [ Thu Mar 02, 2006 12:57 pm ] |

| Post subject: | |

Yes sir, Planes, chisels, some saws, sanding equipment, and don't forget the clamps. A man needs a lot of clamps.... Imagine if you will some wood, a jar of glue and no clamps? I can't. As you probably already know the list gets pretty long once you are settled into it. But then that's half the fun. |

|

| Author: | Joe Beaver [ Thu Mar 02, 2006 1:00 pm ] |

| Post subject: | |

Opps! How was I to know Hesh was going to explain the clamp thing? Oh well...as usual he's right.... |

|

| Author: | Don Williams [ Thu Mar 02, 2006 1:08 pm ] |

| Post subject: | |

One thing I really love is my Lie-Nielson low-angle block plane. It's truly a remarkable tool. It almost works of itself. I swear sometimes it's enchanted. Been reading too many Prydain stories lately... |

|

| Author: | Michael Dale Payne [ Thu Mar 02, 2006 1:49 pm ] |

| Post subject: | |

Clamps, Clamps, Clamps and more clamps. lots of spring clamps in differnt sizes, in particular the med small ones and the large ones I really suggest investing in at least 8-8" and 2- 10" or 12" cam clamps. A wide aray of c-clamps, also 24 spool clamps. You cam make these and I would because as you get more experinced you will more than likly move away from them, but they are in my opinon the best beginer method to attach tops and backs. Oh yea and every piece of void free Birch plywood you can get your hands on. you will be amazed at how much of it you end up using. And yes it is a tool or at least ends-up becoming some of you most used tools in the shop. And as usual do not forget at any cost spiral notebooks and pencils. Keeping a building log will be your most dependable tool. we all learn from both mitakes and success but we learn even quicker when we write them down. You need to aproach every build as if it were a lab class. notes notes and more notes. "I had a new entry last night in mine " changed light bulb over set-up bench, stood on chair to do it. wore one Sitka and rosewood flip flop home  enough said" enough said" |

|

| Author: | Shane Neifer [ Thu Mar 02, 2006 2:18 pm ] |

| Post subject: | |

A couple of my favourites....digital camera. Keep great notes of dimensions, weights (I like the small digital scale I have, adds a bit more detail if you get what you like and want to repeat it), etc but the pictures sure are a handy reference also. I have an ibex instrument makers plane that is y favorite for rough carving brace sides and Lee Valley low angle block plane for various other planing. Nice long paring chisels in the 1/4, 1/2 and 3/4 inch widths are my favorite! I just recieved tapered reamers from Stew Mac yesterday, they are expensive but to get that great fit for bridge and end pins I couldn't think of a better solution. I built my own Fox Bender but am considering buying an electric bending iron, not for sides or cutaways as I have that figured out in my Fox Bender but for tight rosette bends that I am thinking about and for Purfs and Bindings in tight curves. There are many more, good quality drill bits, how will you inlay your rosette, dremel or trimmer? Sometimes your process will dictate your tools. I will leave it here, I am a tool junky and could go on and on....OK one last one..a Parrot Vice from Grizzly of LMI! Shane |

|

| Author: | RichB [ Thu Mar 02, 2006 3:17 pm ] |

| Post subject: | |

I'm new to guitar making too. I have found that sharp chisels & planes are commodities you can't do w/o. If you are making wood products then you most likely have a bandsaw and combination belt/disc sander? I use mine constantly. Exacto saws & blades, & a small alumunim mitre box are also very useful. A thickness gauge, is something I need to get. A good pair of eyes, or magnifying lenses are necessities. John Hall has told me, to buy tools as you need them Oh Yes, and lots of clamps! |

|

| Author: | Alain Desforges [ Thu Mar 02, 2006 3:34 pm ] |

| Post subject: | |

A good straight edge is a big must. You will also appreciate a very flat surface, say, like a granite slab to set up stuff and use as a reference. I also love my nifty little engineering squares I got from Lee Valley (superb for marking fretboards). You will probably want a bending iron for binding/purfling/rosettes. I'm sure there are many things I'm forgetting but as a last thought: Hide glue. Learn it, live it and you'll love it.... |

|

| Author: | Dave Anderson [ Thu Mar 02, 2006 3:38 pm ] |

| Post subject: | |

Some good rasps,files,scrapers,and a sharpning system of some kind,oh yeah ,Don't forget clamps!

|

|

| Author: | Serge Poirier [ Thu Mar 02, 2006 4:07 pm ] |

| Post subject: | |

A good thing to have for novice is a drill press and the thicknessing tool with 3 sharp blades at the bottom that i forget the name if someone can rescue me  . To save money, i would even suggest scrounging stuff like tubing for more molds, screws, bolts and nuts, MDF and iron angles. recycled wood for practicing your developping skills... and lots of stuff to borrow from Mom or girlfriend that i will let the others talk about . To save money, i would even suggest scrounging stuff like tubing for more molds, screws, bolts and nuts, MDF and iron angles. recycled wood for practicing your developping skills... and lots of stuff to borrow from Mom or girlfriend that i will let the others talk about

Good luck with yer new addiction

Serge |

|

| Author: | Martin Turner [ Thu Mar 02, 2006 5:15 pm ] |

| Post subject: | |

Some Japanese water stones are handy for keeping blades and chisels sharp. There are a multitude of theories and methods of sharpening which youll no doubt hear about with time but I try and keep it simple. I run my blades over three King brand water stones..800, 1200 and 600 grit and a leather strop to finish the blade off on. New tools get the face honed and then I work the primary bevel to a mirror finish and then tilt the blade up 3-5 degrees and put in a secondary bevel. Id thoroughly recommend a honing guide of some sort as well...I love the Veritas MkII guide. Other handy tools....lots of cabinet scrapers and a couple of scraper planes. I use a Veritas scraper plane and a Millers Falls No 64 scraper plane on difficult rosewood backs and sides. Dressing scrapers and scraper planes can take a bit of practise but its well worth the effort. Cheers Martin |

|

| Author: | Cocephus [ Thu Mar 02, 2006 5:37 pm ] |

| Post subject: | |

Don`t forget a thickness sander. I`m constantly using mine. Even if you have to build it yourself, it`s time well invested.

|

|

| Author: | Mattia Valente [ Thu Mar 02, 2006 7:37 pm ] |

| Post subject: | |

Clamps - wooden cam clamps, IMO, rule supreme, and will do almost everything you need them to. Light, 1-handed operation, go plenty tight enough. Chisels - buy good ones, don't buy a set with sizes you'll never use. I've got Kirschen (Two Cherries) german-made chisels, lovely stuff, 3mm, 6mm, 8mm and 12mm covers my needs. Plus a slightly wider cranked/bent chisel for glue cleanup Planes - vintage stanley, veritas, lie-nielsen, clifton, all quality stuff. I find myself reaching for my regular block plane (I'm not entirely sure of the point of a low angle block for guitaramking; it's not like I often trim endgrain, and higher angle on more difficult wood = less chance of tearout). Scrapers - buy a selection. Cheap, easy to use, great tools, very versatile. Rasps - Japanese Shinto rasps (hacksaw rasps) are great, as are microplane tools, but a good hand-cut rasp (Nicholson #49 and #50, or the ones StewMac sells, maybe) is a joy to use. I recently took delivery of a pair of Herdim (german-made) hand cut rasps, lovely. Cabinetmakers pattern or half-round are good. Selection of files hand as well for things like nut shaping and such. Sharpening - 'scary sharp' sandpaper on glass, or these days, japanese water stones. Sandpaper's not that cheap if you're using a lot of it, and doesn't last as long. Straightedge - get a good one, minimum 18" long. Measuring tools - get a dial guage (I think Harbor Freight has them in the US) and build a stand, and you've got accurate thickness measurement for all your plates. Scales handy as well, as is a digital camera to document your work, even if it is only for your own purposes. A nice, accurate rule or two is also a must-have. Having said all of that...buy the tools as you find yourself needing them, not all at once. People have different preferences as to what tools they do and do not like using, so there's little point in buying a ton and a half of tools when you're not going to use them all. |

|

| Author: | RussellR [ Thu Mar 02, 2006 9:26 pm ] |

| Post subject: | |

My Favourites are a Japaneese Back Saw, A nice long paring chisel, and the little fret end dressing file from stewmac. But I would say don't rush out and buy everything all at once or you will wind up with a lot of tools you don't use, you willfind your own style . |

|

| Author: | Kim [ Thu Mar 02, 2006 9:43 pm ] |

| Post subject: | |

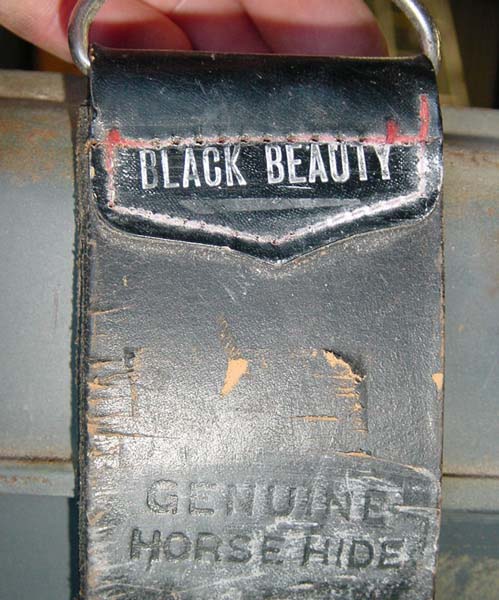

Nut slotting and fret crowning files. You may move toward gobar decks, silicone heat blankets, thicknessing sanders etc that will make other tools you have gathered obsolete, but you will always need a good set of files. Also a Japanese saw rasp seems to be the shaping tool of choice, but I am yet to get my own. And grab yourself a good leather strop, I got one from a flea market for $20.00au, it's a cracker. NOS from the 50's or 60's as supplied to Mens Barber Shops, it's marked "Genuine Horse Hide" and the brand is "Black Beauty"...am I having you on?? Naaaaaaaaahhhhhhh!    Have a look for yourself just like the one Mum used to keep us inline Have a look for yourself just like the one Mum used to keep us inline  . .

Cheers Kim |

|

| Author: | tippie53 [ Thu Mar 02, 2006 9:53 pm ] |

| Post subject: | |

One thing I found more used for than shoes is my granite plate. another thing I don't think I saw mentioned is sanding blocks. I don't use many chisels but the ones I do use are all High quality. You will soon find the cheap tools are a waste of time and money. Allways buy the best you can afford. Also Bending machines and building molds john hall blues creek guitars |

|

| Author: | sfbrown [ Thu Mar 02, 2006 10:09 pm ] |

| Post subject: | |

[QUOTE=peterm] I realized that working on tools and jigs can be more challenging and more time consuming that guitar building itself

Welcome to the club  [/QUOTE] [/QUOTE]

Truer words were never sopken!

Steve |

|

| Author: | Mattia Valente [ Thu Mar 02, 2006 10:33 pm ] |

| Post subject: | |

D'oh. I forgot to mention saws! Japanese-style saws are the canine's nethers, just lovely. I'm not a huge fan of japanese chisels/plane irons (good 'ol tool steel works just fine, thanks), but their saws are fantastic. |

|

| Author: | Serge Poirier [ Thu Mar 02, 2006 11:12 pm ] |

| Post subject: | |

As Hesh just stated, the first big tools you'll need will be common sense and resourcefulness so you don't have to buy everything listed above at first. Also, wisdom and small steps are a great way to get at the top of the hill safely unlike my starting! Good luck bud!

|

|

| Author: | old man [ Fri Mar 03, 2006 1:47 am ] |

| Post subject: | |

A newbie reading all these "requirements" might throw up his hands and quit. I agree that all this stuff is nice and I have most of it, but sift through this material carefully. Many of these tools overlap and can be used to perform multi-functions. Like spool clamps. They are great and I have a nice set of them, but, since I'm using the go-bar deck to glue top and back to sides, they aren't necessary. The point is that everyone here builds a little differently and uses different set-ups. If you need to be frugal, you need to first decide what processes you'll be using and get the tools needed for that method. One very important "saying" that keeps popping up is "there's a lot of ways to skin that cat". Ron |

|

| Author: | Michael Dale Payne [ Fri Mar 03, 2006 2:10 am ] |

| Post subject: | |

Good point Old man.... That’s a phrase I have not used in a long time

Anyway I must say I use my go-bar deck for most all assembly clamping, but do not recommend that a newbie try it on their first few top and back attachments. The chance of damage is great till you get use to using it this way. That the reason I suggest a new builder start with spool clamps. Out side of that Ron is dead on, but it may be hard for a newbie to see the over lap of tools till they have two or three build under their belt. But that is what we do here. Share a huge wealth of knowledge, experience and techniques. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|